KD600 Vector Variable Frequency Inverter AC Drive

380V 11KW 15KW 18.5KW Variable Frequency Inverters For AC Motor

1. Deceleration over excitation function

Accurate thermal simulation platform software ensures the

reliability of thermal simulation.

Each KD600 inverter has undergone thermal simulation testing, and

only the physical prototype is developed within the scope of the

thermal simulation safety design requirements. After the actual

test, the thermal simulation results are very close to the physical

test results. In the limit test state, the thermal simulation can

replace the actual load simulation and an additional layer of

scientific thermal test.

2. Powerful Torque Characteristics

Powerful torque at 0 Hz, without sensors or feedback devices. Until

recently, sensorless control has been out of reach for synchronous

motors.

KD600 series provides powerful starting torque algorithm without

relying on pole sensors or motor feedback.

High-performance current vector control achieves powerful starting

torque with an induction motor.

Brand: K-Drive

Certificate: CE, RoHS

| Model | Power Rating | Input Voltage | Output FREQ | Type |

|---|

| KD600 Series | 0.4kW-900kW | 208-240V / 380-480V 690V ±10% | 0.00-3200.00Hz | DC/AC to AC inverters |

Advantages

Thanks to sophisticated engineers, scientific producing

workmanship, rigorous quality control systems and management team,

K-Drive frequency inverters are equipped with advanced features,

some of which are listed as below:

01. Starting torque: 180% at 0.5Hz (V/f pattern, SVC pattern);

02. Speed adjustable range: 1: 100 (V/f pattern, SVC pattern);

03. Speed accuracy: +/-0.5% (V/f pattern), +/-0.2% (SVC pattern);

04. Over load capability: 150% 1minute, 180% 10seconds;

05. Abundant frequency command sources;

06. Diverse input and output terminals;

07. Ambient temperature: -10°C~50°C;

08. High precise torque constraint, process PID control, multi-speed

control, contracting brake control, field weakening control, all

sides protection, etc;

09. Online and offline auto-tuning of motor parameters can both

performed;

10. Extremely short-time acceleration can be performed without any

trip, such as 0.1s or 0s from 0Hz to 50Hz;

| Mains Supply (L1/L,L2,L3/N) | |

|---|

| Supply voltage | 208-240V ±10% 380-480V 690V ±10% |

|---|

| Power source frequency | 50/60Hz ± 5% |

|---|

| Displacement power factor (cos φ) | (>0.98) |

|---|

| Output Data (U, V, W) | |

|---|

| Output voltage / frequency | 0-100% of supply voltage / 0.00-600.00Hz or customized |

|---|

| Ramp time | 0.01-60000s |

|---|

Note: 150% current can be provided for 1 minute, 180% for 10 seconds.

Higher overload rating is achieved by oversizing the drive.

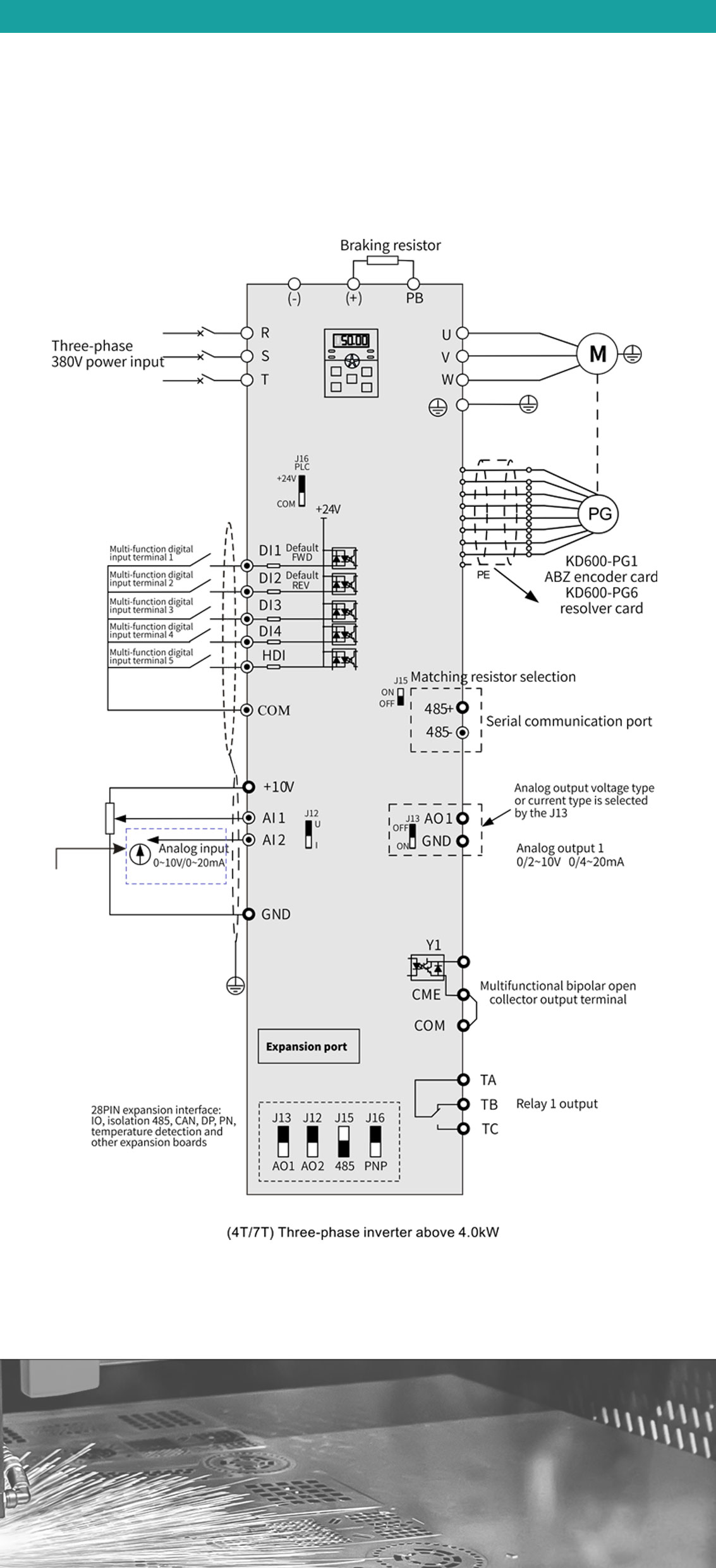

| Digital Input | |

|---|

| Programmable digital inputs | 5 |

|---|

| Logic | NPN or PNP |

|---|

| Voltage level | 22 - 26V |

|---|

| Analog Input | |

|---|

| Analog inputs | 2 |

|---|

| Modes | Voltage or current |

|---|

| Level | 0 to +10V, 0/4 to 20 mA (scalable) |

|---|

| Automatic correction | YES |

|---|

| Relay Output |

|---|

| Programmable relay outputs | 1 |

|---|

| RA - RB / TA - TB | Normally close |

|---|

| RA - RC / TA - TC | Normally open |

|---|

| Contact capacitance | 250 V AC / 3A, 30 V DC / 3 A |

|---|

| Terminal 485 Interface |

|---|

| 485+ / 485- | Rate: 4800/9600/19200/38400/57600/115200 bps Max. distance: 500 m |

|---|

| GND | Isolated from COM |

|---|

| Ambient | |

|---|

| Vibration | Less than 5.9 m/s² (0.6g) |

|---|

| Humidity | Relative humidity 5% - 95 %. No condensation |

|---|

| Corrosive environment | 3C3 |

|---|

| Ambient temperature | -10 ºC - 50 ºC |

|---|

| Altitude | 0 - 2,000 m |

|---|

| Rated output current derated 1% every 100 m above 1,000 m |

|---|

| Storage temperature | -40 - +70 ºC |

|---|

| Efficiency | Efficiency At rated amps: ≥93% |

|---|

| IP grade | IP20 |

|---|

| Cooling method | Forced air cooling |

|---|

| Fieldbus Communication |

|---|

| Modbus RTU, Modbus ASCII | Built-in |

|---|

Applications

KD600 drives are economical series at K-Drive. They offer V/f

control, including voltage and frequency separated control,

adaptable to various industrial applications if sensor-less vector

control is not required, including printing machines, packaging

machines, pumps, fans and blowers, etc.